In the dynamic landscape of manufacturing and automation, cobots have become indispensable assets, working alongside human operators to enhance productivity and efficiency. While cobots offer numerous benefits, ensuring safety during operations helps keep your employees safe while improving efficiency. In this blog, we will explore the best practices for cobot safety, highlighting essential guidelines and precautions that businesses should implement to maintain a secure and collaborative work environment.

Ensuring Safe Automation Operation with Cobots

- Conduct Comprehensive Risk Assessments: Before integrating cobots into your operations, conduct a thorough risk assessment of the workspace. Identify potential hazards and evaluate the risks associated with human-cobot interactions. This assessment will serve as the foundation for developing robust safety protocols and also helps you choose the cobot options that are right for your business.

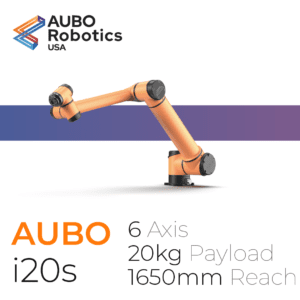

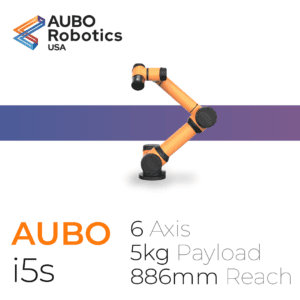

- Choose the Right Cobot for Your Needs: Select cobots that are designed for safe human-robot collaboration. The AUBO i-Series cobots, for example, are equipped with advanced safety features, such as force and speed limitations, to prevent injuries in case of unintended contact with humans, they also include 16 redundant designed dual IO ports for additional safety, regardless of the use case.

- Provide Adequate Training: Ensure that all employees who work with cobots undergo comprehensive training on cobot safety protocols and procedures. Training should cover safe operating practices, emergency shut-off procedures, and guidelines for interacting with cobots during operations. AUBO Cobots have in-built safety measures to ensure safe operation even during power failure, be sure your employees know what these features do and don’t.

- Regular Maintenance and Inspection: Perform routine maintenance and inspections on cobots to ensure they are operating at optimal safety levels. Regularly check for wear and tear on components, and promptly address any issues identified during inspections. AUBO offers modular cobots that are simple to dismantle so any joint can be swapped or replaced easily. Though component failure is rare as AUBO cobots are rigorously tested and all our cobots have highly measured MTBF values, ensuring their reliability throughout their life span. Plus, all AUBO cobots come with a limited industry leading 18-month warranty.

- Implement Additional Safety Features: Clear and effective communication methods between cobots and human workers are important to ensure safety. Visual indicators, audible alarms, or signals can alert workers to a cobot’s status and movements. While safety sensing and imaging systems can ensure that operations come to a halt if an object is detected in the cobot’s work area. Because AUBO Cobots are open architecture based and non-proprietary, they integrate with all standard alarm, signal, and safety sensing systems and AUBO products are integrated with a vast ecosystem of safety equipment manufacturers.

Safety is the cornerstone of successful human-cobot collaboration. By following best practices for cobot safety, businesses can create a secure working environment, mitigate risks, and unlock the full potential of cobots to enhance productivity and efficiency. With the advanced safety and open architecture features of AUBO i-Series cobots, companies can confidently embrace collaborative automation, while keeping safety a top priority. To embark on your journey towards a safer and more efficient workplace, contact an automation expert today.