i-Series

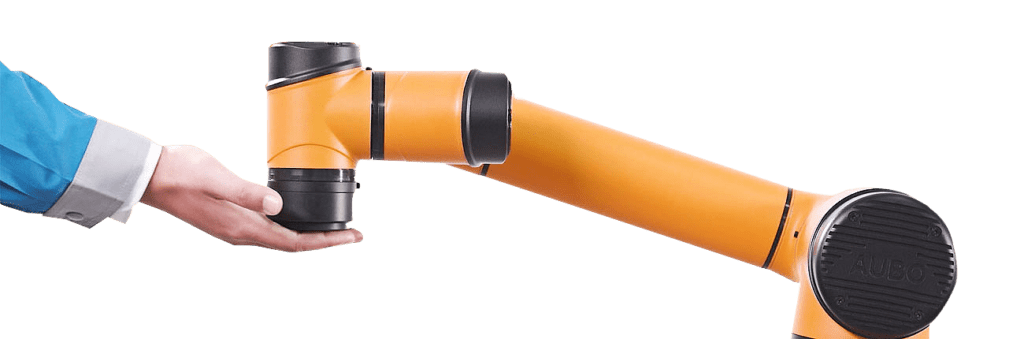

Built for collaboration.

Our flagship cobots combine ease of use, precision, and safety you can trust. The i-series line is developed with fully open architecture, designed to be simple to operate out of the box while retaining full-programming customizability, so your team can benefit from the flexibility to automate any process in your workflow.

The i-Series cobots are available in 3,5,10,16, and 20 kg payload options.

Compare models below to find out which collaborative robot arm is the best fit for you.

Which cobot is best for you?

3 KG

Max Payload

16 KG

Weight

± 0.02mm

Repeatability

625mm

Reach

5 KG

Max Payload

24 KG

Weight

± 0.02mm

Repeatability

886.5mm

Reach

10 KG

Max Payload

38.5 KG

Weight

± 0.03mm

Repeatability

1350mm

Reach

16 KG

Max Payload

38KG

Weight

± 0.03mm

Repeatability

967.5mm

Reach

20 KG

Max Payload

63 KG

Weight

± 0.1mm

Repeatability

1650mm

Reach

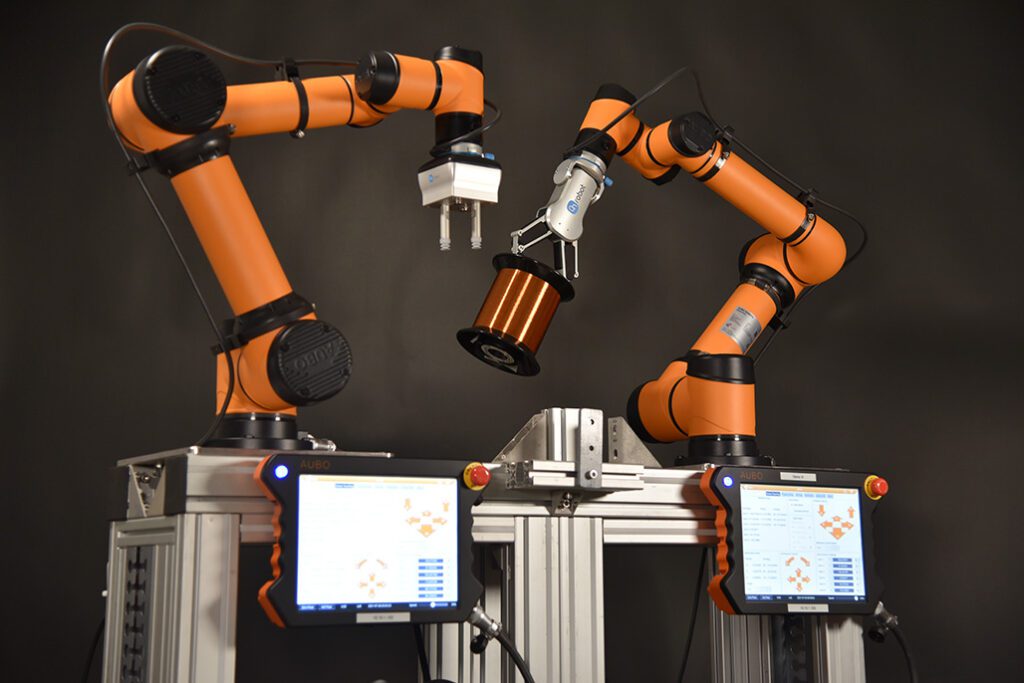

The AUBO Advantage

Open Innovation

We develop cobots that feature fully open architecture so your team can entirely customize our cobots to help meet the goals and needs of your organization.

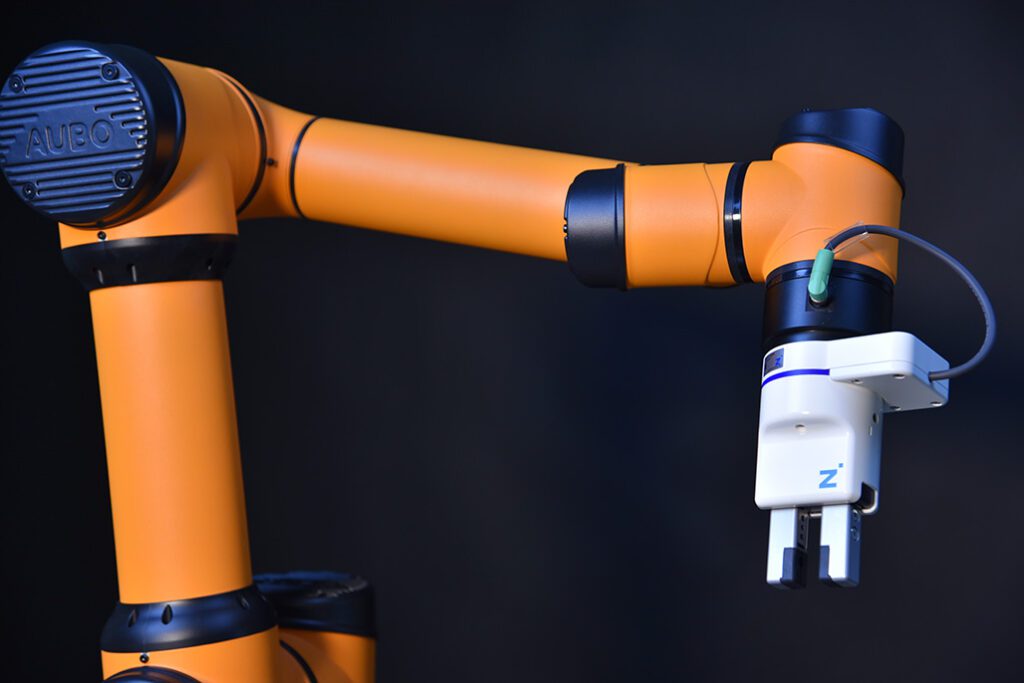

Never Proprietary

AUBO cobots are ISO 150 compliant so they integrate with all standard end-of-arm tooling. We promise to never force you to buy into an ecosystem of products or software.

Application Agnosticism

The i-Series cobots are built to integrate fully and easily into your existing application workflow. Regardless of the use case or industry, we can help customize a solution for you.

Ease of Use and Operation

Out-of-the box, it takes less than 30 minutes for an untrained user to learn how to program their first simple task. Our teach pendant features a simple to use visual drag and drop system for cobot operation, so you can tap into the full benefits of collaborative automation without knowing a single line of code.

If you need a more granular solution – our cobots are entirely customizable and feature an open architecture platform allowing deep integration with various third-party plug-ins, APIs, and full SDK configurability.

Designed to be Modular and Flexible

AUBO cobots are lightweight and compact, featuring a minimal footprint for easy deployment across applications – within four hours on average. With 6-degrees of freedom, each cobot is designed to retain flexibility regardless of the work space, regardless if bench-mounted or used for machine tending. Every joint in an AUBO Cobot is designed to be fully modular, so in the rare case that a cobot needs servicing any joint can be swapped out quickly and easily.

Safety and Quality Assurance

The AUBO i-Series cobots are certified EN ISO 13849-1:2015 (PL=d, CAT 3), ISO/TS 15066:2016 (excluding i20**) UL, CE, and SEMI S2 compliant, with 10-levels of customizable collision detection and sensory safety, in the case of power loss: every servo has a braking system to lock position – even if holding a heavy object. Additionally, the 16 safety I/O interfaces include redundant design and circuitry to ensure safety features function in the case of a single port failure.

All AUBO cobots pass rigorous quality assurance and failure rating tests with 500+ testing criteria and 90+ dedicated testing sections from parts to the arm assembly. You can feel confident in the i-Series’ durability since we’ve done repeated tests to ensure the safety of our robots during operation.